Ideal applications

Very low VOCs concentrations

2021 官網陞級中!眼前現今您訪問官網的瀏覽器設備分辯率寬度低於1280px

請利用高分辯率寬度訪問。

When catalyst is added to the media chambers of an RTO it is then referred to as an RCO. With the use of catalyst, the VOC compounds will oxidize at lower temperatures and converts to CO2 and water vapor, further lowering the need for auxiliary energy.

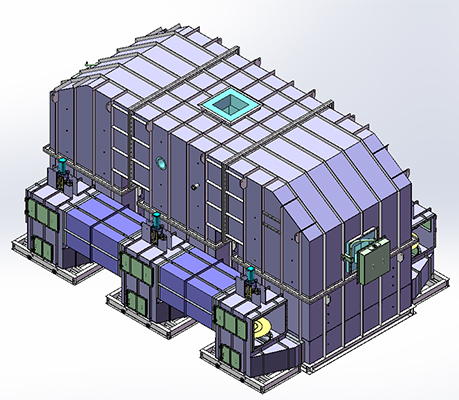

Regenerative Catalytic Oxidizer (RCO) consists of two or more insulated chambers filled with high temperature ceramic media. In operation, the process stream enters the oxidizer via an energy recovery chamber where the ceramic heat transfer media preheats it prior to introduce it into the oxidation chamber. As the process stream passes up through the inlet bed, its temperature rapidly increases. After the oxidation reaction occurs at the combustion chamber through the catalyst, the pollutant laden stream is converted into CO2 and water vapor, and release a large amount of thermal energy. The hot, clean gas exit via the 2nd recovery bed and leave the heat in the ceramic media to preheat the inlet process stream in the next gas flow cycle.

With the combination of catalyst and the ceramic heat transfer media, RCO greatly reduce the fuel consumption during thermal oxidization and the preheating gas flow, and further lower the operating cost.

Very low VOCs concentrations

1.Two-chamber or multi-chamber configurations;

2.Various burner options including electric heating elements or multiple gas fuel inputs (natural gas, propane, hydrogen) and ultra-low NOx.

3.Supplemental Fuel Injection (SFI);

4.Secondary Heat and Energy Recovery systems for waste heat utilization.

5.Acid gas scrubber module with a completely integrated control system.